Inspection Services

Perry Technology has a full complement of advanced inspection equipment, including seven ZEISS CMMs equipped with rotary tables and gear inspection software, as well as multiple Gleason and Hofler Gear CMMs. We have what it takes to rigorously monitor the quality of our parts.

General Inspection

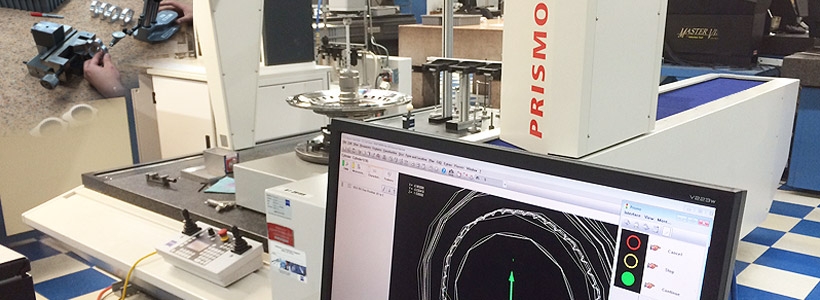

Our primary objective is ensuring that all the parts we produce conform to our customer's requirements. In order to achieve this objective, we use a squadron of Zeiss Prismo CMMs, TESA-scan optical comparators, and highly trained programmers and inspectors to operate them.

All the gauges and instruments in our inspection department are traceable to NIST standards and are on a recall cycle based on the type of device or standard.

These recalls are monitored by GageTrak calibration software, with CMMs and larger more complex inspection systems calibrated and maintained by the OEM.

Our Quality Systems are in compliance with and registered to ISO 9001:2015 and AS9100D, so you can be sure that we have the systems in place to support processes to meet your requirements.

Gear & Spline Inspection

Our inspection department is equipped with state-of-the-art equipment to verify the accuracy of the gears and splines we produce. Our Gleason and Höfler equipment can measure any gear, helical, spline, worm, bevel, or spiral bevel up to 30" diameter.

Zeiss CMM Inspection

For complex and production inspection we use (7) Zeiss Prismo CMMs, two of which are equipped to handle parts up to 48" in diameter.

In addition to handling individual parts, the larger machines are equipped to inspect on a palletized production basis.

We use our smaller machines for 3 and 4 axis inspection of complex geometries, and have located them in several areas throughout the shop for selected departmental use.

All of our Zeiss CMMs use GearPro software that allows inspection of any gear or spline form. Several of our machines also have rotary tables to allow full back-up of our more conventional gear inspection equipment.

Certified Quality Control Technicians

Some of our gear inspectors hold delegated inspection and sourcing accreditations issued by our customers. This allows specific sign off on final part acceptance, saving precious time that might otherwise be consumed by a Source Inspector.

https://www.perrygear.com/quality-inspection/inspection-services#sigProId13ae6c0e36