Reverse Engineering

Customers call on us to reverse engineer parts for reasons such as evaluating and improving on a design, because replacement parts are unavailable, or because lead time/pricing for obtaining replacements are unacceptable.

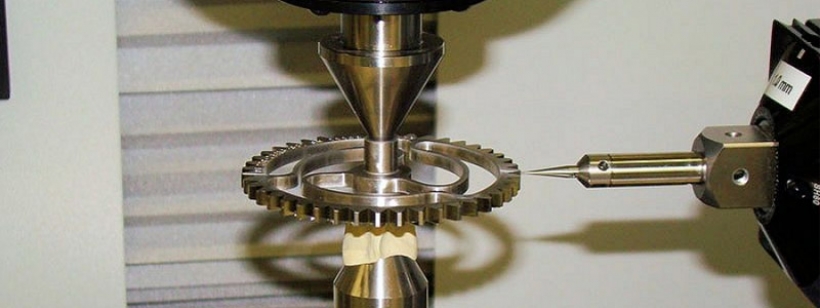

Using our ZEISS coordinate measuring machines in combination with various inspection techniques, we take detailed measurements of your part and then reconstruct it into a 3-D computer model. From the 3-D model, we can quickly go from design to production using our state of the art CAM equipment. In many cases we will print a 3-D model of a reverse engineered part so we can validate the measurements or to test functionality.