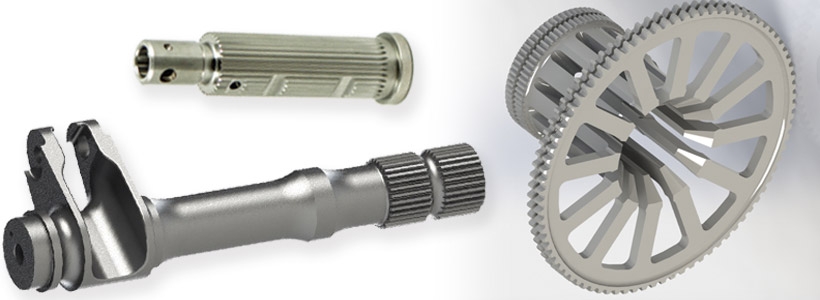

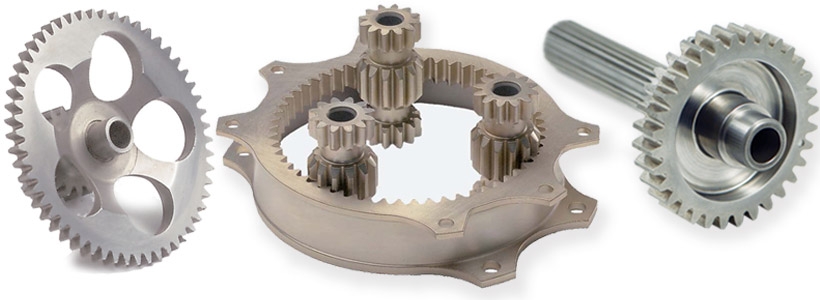

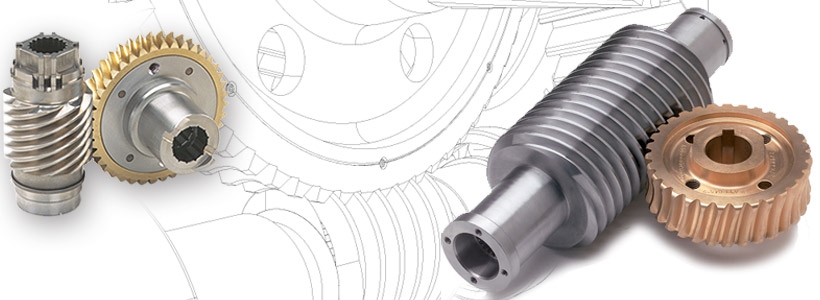

Gears and Splines

Because Perry Technology services so many different industries, we understand the unique demands and requirements involved in meeting our customers expectations of quality.

In addition to understanding industry specific requirements, we understand the unique requirements of every part we produce.

When you work with Perry Technology, you are not simply entering into another customer / vendor relationship, you are entering into a partnership. From the beginning, our engineering department works closely with you to thoroughly understand your needs. We'll review your design specifications and, where appropriate, advise you on matters such as material and performance considerations based on the part's application.

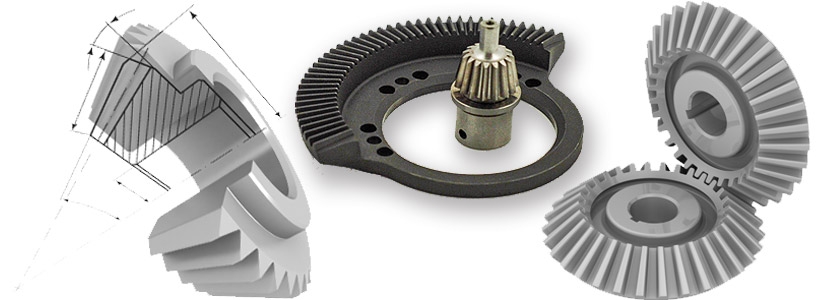

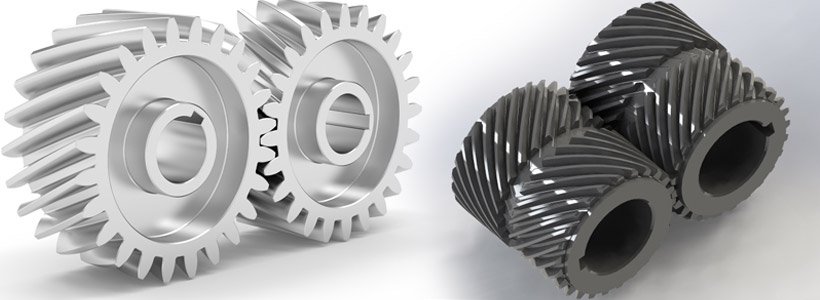

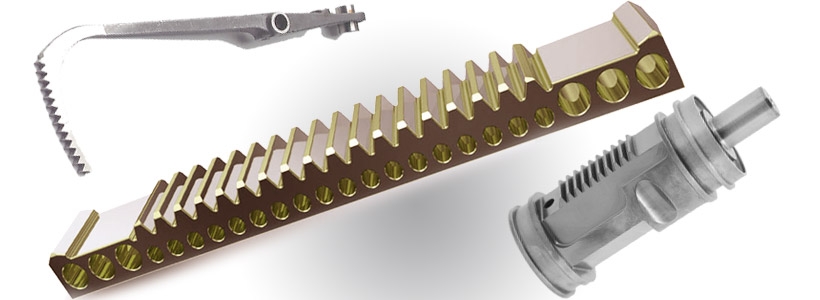

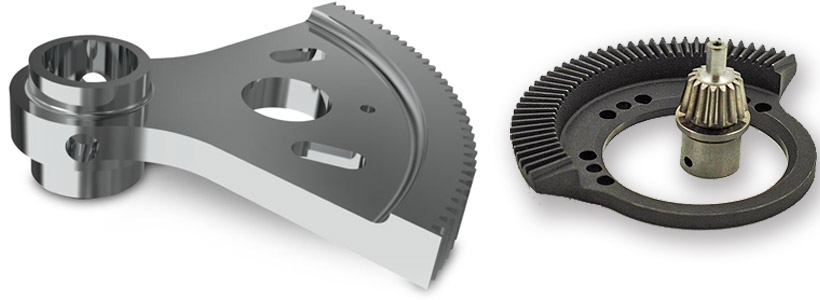

From helical gears used in flight critical helicopter and aircraft turbines, to corrosion resistant bevel gears used in military applications, to miniature rack gears used in precision medical equipment, Perry Technology has over 70 years of experience and expertise to successfully produce your gear or spline.

We manufacture parts complete, or we can perform just a single operation such as tooth cutting or grinding. For all of our subcontracted work, we offer fast turnaround times, so your projects stay on time and within budget.

Perry Technology is dedicated to meeting our customers stated requirements. Contact us today for all your gear and spline needs.